- -The company acquires 4th 100% owned Lithium project-Lithman North Project is 15 kilometers to the northwest of the Tanco Mine site in southeast Manitoba-The Tanco Mine was Canada’s largest producer of Spodumene, Tantalum and Cesium, producing from the Tanco Pegmatite

-Spodumene is mined from Pegmatites and is one of the primary Lithium ore minerals in hard rock Lithium mines

-Lithman North project is situated approximately 17 kilometers to the northwest of the Lithium West Project and 12 kilometers north of the Lithium One Project.

-To date this brings the total amounts of company’s claims in the Winnipeg River Pegmatite Field to 21, for a total of 3,691 hectares (9,120 acres)

June 15th, 2016 Vancouver, Canada / Pacific North West Capital Corp. (“PFN”, the “Company”) (TSX.V: PFN; Frankfurt: P7J.F; OTCQX: PAWEF announces that it has acquired another Lithium project in southeast Manitoba through staking. The project will be held by Lithium Canada, which is a 100% subsidiary of PFN.

The Lithman North Project is situated to the northwest of the present day Tanco Mine, which currently is producing Cesium Formate, a completion fluid for the petroleum industry. The Tanco Mine, was previously known as North America’s largest producer of Spodumene, Tantalum and Cesium. Spodumene is one of the primary Lithium ores minerals in hard rock Lithium mines. The 100% owned project consists of 3 claims for a total area of 372 hectares (919 acres).

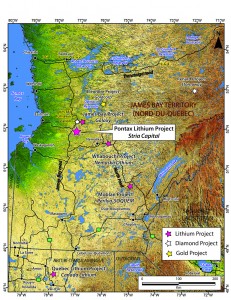

Click Image To View Full Size

The project area is situated in the Bird River Greenstone Belt and was staked to cover several large Pegmatites as found on government maps. The Pegmatites have had little exploration and there are no historical records. A field review of the Pegmatites showed them to be Albite Pegmatites with a complex mineralogy. Field work is being planned to explore them for the summer of 2016. They are located approximately 15 kilometers to the northwest of the Tanco Minesite and on the northern margin of the Winnipeg River Pegmatite Field.

The Tanco Pegmatite was discovered on the west side of Bernic Lake from surface drilling in the 1920’s. The mine went into production in 1969 and has produced over the years, in varying capacity, and is still producing today. It is a buried Pegmatite and not exposed at surface, except for under Bernic Lake. It is an extremely fractionated, rare-metal, complex type-Petalite subgroup, LCT (Lithium-Cesium-Tantalum) Pegmatite and is hosted by a late stage, subvolcanic Gabbro. The total tonnage of the Tanco Gabbro Pegmatite has been calculated to be approximately 25 million tons. It is a part of the Bernic Lake Pegmatite Group of the Winnipeg River Pegmatite Field.

The company considers the Lithman North Project to have the potential to host additional Lithium-bearing Pegmatites similar to others found in the region. The area has strong infrastructure and is an active mining area. The staking of this additional ground has increased the claims in the Winnipeg River Pegmatite Field to 21 for a total of 3,691 hectares (9,120 acres). Lithman North Project is situated approximately 17 kilometers to the northwest of the Lithium West Project and 12 kilometers north of the Lithium One Project. The project has excellent infrastructure and is located approximately 150 km (93 miles) northeast of the provincial capital, Winnipeg. Claims are to the east of Bird Lake and a gravel based highway (HWY 315) runs through the project area.

With respect to the Lithman North Project, a finder’s fee in the amount of 60,000 shares of the Company is payable to Carey Galeschuk. The finder’s fee is subject to TSX Venture Exchange approval.

All shares issued in connection with the finder’s fee are subject to a four month and one day hold period from the date of issuance.

Further announcements with regards to joint venture partners and exploration plans will be forthcoming.

About The Company’s Lithium Division

The company’s new Lithium Division will focus on the acquisition, exploration and development of Lithium Projects in Canada. In the United States the company will use its wholly owned U.S.A subsidiary to acquire and develop projects in active mining camps in Nevada, Arizona and California.

Management believes that these new age metals, Lithium, PGM’s and Rare Earths, have robust macro trends with surging demands and limited supply. Going forward, this new division will explore for the minerals needed to fuel the demand for energy storage and other core 21st Century Technologies.

The company has a growing portfolio of Lithium projects. The Clayton Valley Forks Li Project in Nevada is a recent Lithium brine project acquired by the company (PFN News Releases April 25th, 2016 and May 9th, 2016). The company also has hard rock Lithium projects in Canada (PFN News Releases April 21st, 2016 and May 24th, 2016).

Lithium and Platinum Group Metal prices have improved dramatically in recent months. Lithium supplies remain in deficit relative to their demand. Both metals groups are used for the expanding worldwide automobile industry (conventional and electric). In the case of PGM’s, demand is increasing for autocatalysts, a key component for reducing toxic emissions for automotive, gasoline and diesel engines. In regards to Lithium, there is an ever increasing demand for batteries in cellphones, laptops, electric cars, solar storage, wireless charging and renewable energy products.

About the company’s Platinum Group Metals Division

Achievements to date and future plans for River Valley are outlined below as follows:

- 1.PFN currently has 100% ownership in the River Valley Project, subject to a 3% NSR, with options to buy down

- 2.Completed exploration and development programs on the River Valley property include more than 600 holes drilled since year 2000 and several mineral resource estimates and metallurgical studies;

- 3.Results for the current (2012) mineral resource estimate are below;

- 4.2015 drill program confirms new high grade T2 discovery

Click Image To View Full Size

- 5.Exploration and development plans outlined for 2016

- 6.Ongoing strategic partner search for River Valley project

- 7.Results for the most recent Metallurgical Testwork Study are summarized below:

– Prepared by Tetra Tech (formerly Wardrop)

– High Confidence: Measured plus Indicated = 72% of total

– Reported on PdEq basis: Pd=40% & Pt=20% of the payable metals

– Pd to Pt ratio = 2.5:1; Cu to Ni ratio = 3:1

– High Grade potential, particularly in the north part of River Valley deposit

– Resources under evaluation for development potential as open pit mining operation

Click Image To View Full Size

Click Image To View Full Size

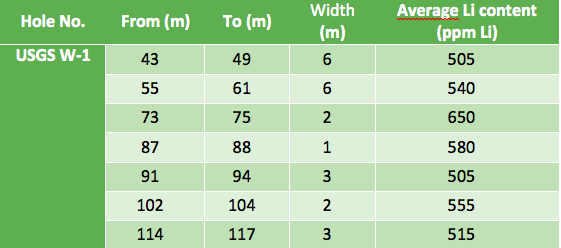

- 8.Results for the 2015 discovery drill program on the T2 target are as follows:

-Drill hole intercepts much higher than the average grade of current mineral resource estimate

-Possible new mineralized zone at the north end of the River Valley deposit

-Show potential to take the River Valley PGM Project in a new direction

-More drilling required

Click Image To View Full Size

- 9. Exploration and Development Plans for 2016

- -Mineral prospecting and geological mapping on surface-Drill programs targeted to add more higher grade ???-Geological interpretation and 2D/3D modelling of all drill and surface results

-Application to the OPA’s Junior Exploration Assistance Program (JEAP) for 33% refund of all exploration expenditures up to $300,000.

-Ongoing Strategic Partner Search for River Valley

QUALIFIED PERSON

The contents contained herein that relates to Exploration Results or Mineral Resources is based on information compiled, reviewed or prepared by Dr. Bill Stone, Principal Consulting Geoscientist for Pacific North West Capital. Dr. Stone is the Qualified Person as defined by National Instrument 43-101 and has reviewed and approved the technical content.

On behalf of the Board of Directors

” Harry Barr ”

Harry Barr

Chairman and CEO

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Cautionary Note Regarding Forward Looking Statements. This release contains forward-looking statements that involve risks and uncertainties. These statements may differ materially from actual future events or results and are based on current expectations or beliefs. For this purpose, statements of historical fact may be deemed to be forward-looking statements. In addition, forward-looking statements include statements in which the Company uses words such as “continue”, “efforts”, “expect”, “believe”, “anticipate”, “confident”, “intend”, “strategy”, “plan”, “will”, “estimate”, “project”, “goal”, “target”, “prospects”, “optimistic” or similar expressions. These statements by their nature involve risks and uncertainties, and actual results may differ materially depending on a variety of important factors, including, among others, the Company’s ability and continuation of efforts to timely and completely make available adequate current public information, additional or different regulatory and legal requirements and restrictions that may be imposed, and other factors as may be discussed in the documents filed by the Company on SEDAR (www.sedar.com), including the most recent reports that identify important risk factors that could cause actual results to differ from those contained in the forward-looking statements. The Company does not undertake any obligation to review or confirm analysts’ expectations or estimates or to release publicly any revisions to any forward-looking statements to reflect events or circumstances after the date hereof or to reflect the occurrence of unanticipated events. Investors should not place undue reliance on forward-looking statements.