- Ministry of Mines is prepared to grant Mining License 215 (ML215) for its Aukam Graphite Property in Namibia.

- Gratomic can now produce a concentrate of up to 98% Cg

- Management has subsequently decided to build a 20 000 tonne per annum processing plant.

Gratomic Inc. is pleased to announce, supplementary to its February 21, 2020 Press Release, that it has received a Notice from the Ministry of Mines and Energy of Namibia that the Minister is prepared to grant Mining License 215 (ML215) for its Aukam Graphite Property in Namibia. The License area falls within the proximity of the Aukam Processing Plant and the Graphite bearing shear zone for a total of 5002 hectares (5002 ha). Securing the mining license is a critical step towards moving the Aukam Mine into commercial production.

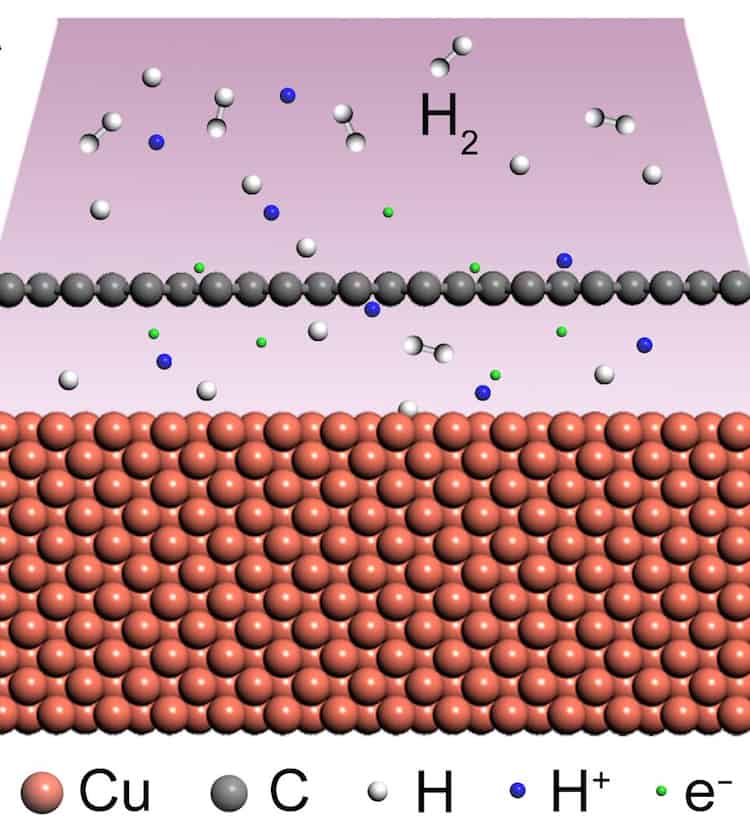

The Company has completed 8 months of pilot testing on historically mined product and conducted an internal study on the efficiency of the pilot processing facility on this material. Through rigorous testing and adjustments to the plant, Gratomic can now produce a concentrate of up to 98% Cg. Management has subsequently decided to build a 20 000 tonne per annum processing plant. To date, 90% of construction is complete. Upon completion of the remaining 10%, the Company will initially start processing material from historical workings left at the surface when the mine last operated in 1974.

The Company has recently appointed Dr. Ian Flint to complete a preliminary economic assessment on the Aukam Processing plant. The study, its recommendations, and their subsequent implementation, will ensure the scale up of the existing pilot plant to a commercial scale processing facility that will provide the desired concentrate grades and production rates.

With respect to site exploration, in the coming months diamond drilling will resume at Aukam Graphite. The drilling will be conducted utilizing Company owned drilling equipment, focusing on areas proximal to graphite mineralization, depicted by previous diamond drilling, underground excavation and surface outcrop sampling. The drill targeting will be systematic with the expectation of producing an NI 43-101 resource estimate.

Arno Brand, President and CEO of the Company stated that “the Company will be able to satisfy all of the conditions in the Notice and proceed to commercialization of its Aukam Graphite Mine. This marks a significant milestone for the Company.”

Risk Factors

No mineral resources, let alone mineral reserves demonstrating economic viability and technical feasibility, have been delineated on the Aukam Property. The Company is not in a position to demonstrate or disclose any capital and/or operating costs that may be associated with the processing plant.

The Company advises that it has not based its production decision on even the existence of mineral resources let alone on a feasibility study of mineral reserves, demonstrating economic and technical viability, and, as a result, there may be an increased uncertainty of achieving any particular level of recovery of minerals or the cost of such recovery, including increased risks associated with developing a commercially mineable deposit.

Historically, such projects have a much higher risk of economic and technical failure. There is no guarantee that production will begin as anticipated or at all or that anticipated production costs will be achieved.

Failure to commence production would have a material adverse impact on the Company’s ability to generate revenue and cash flow to fund operations. Failure to achieve the anticipated production costs would have a material adverse impact on the Company’s cash flow and future profitability.

Steve Gray, P. Geo. has reviewed and approved the scientific and technical information in this press release and is the Company’s “Qualified Person” as defined by National Instrument 43-101 – Standards of Disclosure for Mineral Projects.

About Gratomic Inc.

Gratomic is an advanced materials company focused on mine to market commercialization of graphite products most notably high value graphene-based components for a range of mass market products. We have a Joint Venture collaboration with Perpetuus Carbon Technology, a leading European manufacturer of graphenes, to use Aukam graphite to manufacture graphene products for commercialization on an industrial scale. The Company is listed on the TSX Venture Exchange under the symbol GRAT.

For more information: visit the website at www.gratomic.ca or contact:

Arno Brand at [email protected] or 416 561-4095