Lomiko Metals Inc. is focused on the exploration and development of graphite for the new green economy. Lomiko has been monitoring emerging legislation aimed at reducing dependence on Chinese supply of graphite, lithium and other electric vehicle battery materials. One hundred per cent of graphite is currently imported to the United States as there are no domestic graphite mines able to produce material for graphite anodes used in electric vehicles. Please also refer to news releases dated Sept. 9, 2020, and Oct. 7, 2020, related to changing government policies regarding critical minerals.

U.S. Election Bonus for Critical Minerals Mining

In a boon for the critical minerals mining industry, former vice-president and current presidential frontrunner Joe Biden’s campaign has privately told U.S. miners it would support boosting domestic production of metals used to make electric vehicles, solar panels and other products crucial to his climate plan, according to three sources familiar with the matter.

Mr. Biden, who served as Barack Obama’s vice-president and is well regarded in conservation circles, has been expected to continue in that vein. The U.S. Democratic presidential candidate also supports bipartisan efforts to foster a domestic supply chain for graphite, lithium, copper, rare earths, nickel and other strategic materials that the United States imports from China and other countries, the sources said. Mr. Biden is also well regarded by the Canadian government on issues of mining and green energy which has a Canada-U.S. supply strategy agreement.

On Sept. 28, 2020, Canadian ministers discussed opportunities to drive Canada’s natural resources advantage by building on Canada’s strong environmental, social and governance performance record to attract investment, generate new value chains and create job opportunities across Canada, including for indigenous businesses and communities. Ministers agreed that an inclusive approach that builds capacity and ensures diversity is a key ingredient to Canada’s successful economic recovery.

Co-chaired by Seamus O’Regan, Canada’s Minister of Natural Resources, and Ranj Pillai, Deputy Premier and Minister of Energy, Mines and Resources for Yukon, they agreed to work together to build an all-Canadian critical minerals and battery value chain across sectors and pursue engagement with Lomiko’s partners in the United States and beyond.

“Canada’s economy is in a strong position to recover and excel post-COVID because of our natural resource potential. All communities across Canada should play a part, whether it is contributing critical minerals to the supply chain, advancing innovative energy development, or adding jobs and capacity to our remote and northern communities,” said Mr. Pillai.

Lomiko’s opportunity in the supply chain

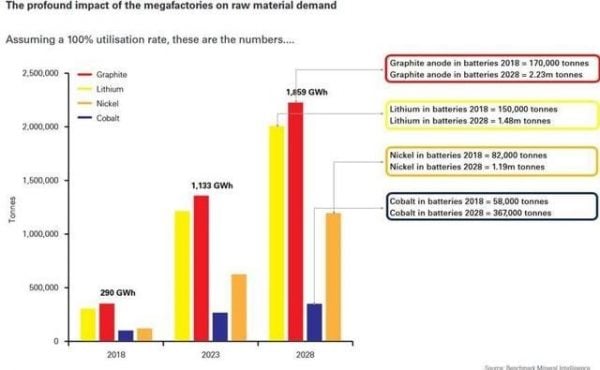

Graphite demand is expected to increase exponentially for the mined natural graphite material, as more is used in the production of spherical graphite for graphite in the anode portion of electric vehicle lithium-ion batteries.

With the completion of a $750,000 financing on Oct. 23, 2020, Lomiko plans to work on its near-term goals as follows:

- Complete 100-per-cent acquisition of the property, currently 80 per cent owned by Lomiko Metals;

- Complete metallurgy and graphite characterization to confirm lithium-ion anode-grade material;

- Complete a technical report to confirm the extent of the mineralization equals or surpasses the nearby Imerys mine, owned by an international mining conglomerate;

- Complete preliminary economic assessment (PEA).

Volkswagen

Volkswagen