- Provided update on promising results emanating from electrochemical performance tests performed on materials produced with our GEN2 PUREVAPTM Quartz Reduction Reactor

- Material produced with the GEN2 PUREVAPTM QRR, demonstrated its potential to advantageously replace graphite in Lithium-ion (Li-ion) batteries while limiting the disadvantages inherent to silicon anodes

MONTREAL, April 15, 2020 — HPQ Silicon Resources Inc.  (“HPQâ€Â or the “Companyâ€) TSX-V: HPQ; FWB: UGE; Other OTC : URAGF; would like to update its shareholders on promising results emanating from electrochemical performance tests performed on materials produced with our GEN2 PUREVAPTM Quartz Reduction Reactor (“QRRâ€).

Recently, tests conducted at the Institut National de Recherche Scientifique (INRS), on material produced with the GEN2 PUREVAPTM QRR (“GEN2â€), demonstrated its potential to advantageously replace graphite in Lithium-ion (Li-ion) batteries while limiting the disadvantages inherent to silicon anodes.

“While preliminary, the results obtained are very promising and validate our decision to focus our efforts on upstream production of materials needed to make the silicon-based anodes for high-density lithium-ion battery using material produced by our PUREVAPTM RRQ process as feed stock,†said Bernard Tourillon, President and CEO HPQ Silicon. “Interest in Silicon Metal’s potential to contribute to energy storage demand is undeniable and generating massive investments, as well as serious industry interest.â€

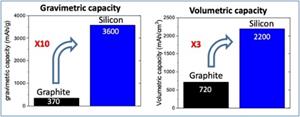

SILICON (Si), A SUPERIOR ANODE MATERIAL FOR LITHIUM-ION BATTERIES VERSUS GRAPHITE

Silicon (Si) is a very promising anode material for Li-ion batteries because it’s theoretical gravimetric capacity (storage capacity in (mAh) per g of material) and volumetric capacity (storage capacity in (mAh) per cm3 of material) are significantly higher than graphite, the material currently used in commercial Li-ion batteries. While resolving silicon swelling and cracking during the lithiation phase1 represents a significant challenge in order to achieve a comparable cyclage stability to graphite, the reference anode material of Li-ion batteries, the promising results obtained represent a step forward in that direction.

The tests on material produced with the GEN2 are part of a series of initiatives being undertaken by HPQ in order to become a producer of silicon (Si) materials suitable for the next generation Li-Ion batteries. The tests were completed at the Centre Énergie Matériaux Télécommunications (EMT) of the INRS by Professor Lionel ROUÉ under an NSERC Engage Grant and a NSERC Engage plus Grant.

The exact composition of the material produced with the GEN2 as well as how the electrodes used in the tests were prepared are trade secrets of HPQ. HPQ will take the necessary steps to protect this invention. As part of this research project, HPQ retains all intellectual property rights in relation to this invention.

SILICON (Si) FOR LITHIUM-ION BATTERIES: A GROWING MARKET

A recent report by Wood Mackenzie Power projects that energy storage deployments are estimated to grow +1,300% from a 12 Gigawatt-hour market in 2018 to a 158 Gigawatt-hour market in 2024. This is why, despite the low utilization rate of silicon-based powders in current Li-ion batteries, demand for silicon (Si) based powders is estimated to represent an addressable market of US $ 1B by 20222 expanding at a CAGR of 38.9% between 2019 – 2024.

About Silicon

Silicon (Si), also known as silicon metal, is one of today’s strategic materials needed to fulfil the Renewable Energy Revolution (“RERâ€) presently under way. Silicon does not exist in its pure state; it must be extracted from quartz (SiO2), in what has historically been a capital and energy intensive process.

About HPQ Silicon

HPQ Silicon Resources Inc. (TSX-V: HPQ) is building a portfolio of unique high value silicon products needed for the RER.

Working with PyroGenesis Canada Inc. (TSX-V: PYR), a high-tech company that designs, develops, manufactures and commercializes plasma – based processes, HPQ is developing:

- The PUREVAPTM “Quartz Reduction Reactors†(QRR), an innovative process (patent pending), which will permit the one step transformation of quartz (SiO2) into high purity silicon (Si) at reduced costs, energy input, and carbon footprint that will propagate its considerable renewable energy potential;

- HPQ is in the process of becoming the lowest cost (Capex and Opex) producer of silicon (Si) and high purity silicon (3N – 4N Si);

- The PUREVAPTM Silicon Nano Reactor (SiNR), a new proprietary process that can uses different purities of silicon (Si) as feedstock, to make spherical silicon nanopowders and nanowires;

- HPQ objective is to become the lowest cost manufacturer of spherical Si nanopowders and silicon-based composites needed by all the manufacturers of next-generation lithium-ion batteries;

- During the coming months, spherical Si nanopowders and nanowires silicon-based composites samples requested by industry participants and research institutions’ will be produced using the newly upgraded Gen2 PUREVAPTM SiNR.

HPQ is also working with industry leader Apollon Solar of France to:

- Use their patented process and develop a capability to produce commercially porous silicon (Si) wafers and porous silicon (Si) powders;

- The collaboration will allow HPQ to become the lowest cost producer of porous silicon wafers for all-solid -state batteries and porous silicon powders for Li-ion batteries.

- The plan is to deliver porous Si wafer to a battery manufacturer (under NDA) for testing in 2020.

This News Release is available on the company’s CEO Verified Discussion Forum, a moderated social media platform that enables civilized discussion and Q&A between Management and Shareholders.

Disclaimers:

The Corporation’s interest in developing the PUREVAP™ QRR and any projected capital or operating cost savings associated with its development should not be construed as being related to the establishing the economic viability or technical feasibility of any of the Company’s Quartz Projects.

This press release contains certain forward-looking statements, including, without limitation, statements containing the words “may”, “plan”, “will”, “estimate”, “continue”, “anticipate”, “intend”, “expect”, “in the process” and other similar expressions which constitute “forward-looking information” within the meaning of applicable securities laws. Forward-looking statements reflect the Company’s current expectation and assumptions and are subject to a number of risks and uncertainties that could cause actual results to differ materially from those anticipated. These forward-looking statements involve risks and uncertainties including, but not limited to, our expectations regarding the acceptance of our products by the market, our strategy to develop new products and enhance the capabilities of existing products, our strategy with respect to research and development, the impact of competitive products and pricing, new product development, and uncertainties related to the regulatory approval process. Such statements reflect the current views of the Company with respect to future events and are subject to certain risks and uncertainties and other risks detailed from time-to-time in the Company’s on-going filings with the security’s regulatory authorities, which filings can be found at www.sedar.com. Actual results, events, and performance may differ materially. Readers are cautioned not to place undue reliance on these forward-looking statements. The Company undertakes no obligation to publicly update or revise any forward-looking statements either as a result of new information, future events or otherwise, except as required by applicable securities laws.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

For further information contact

Bernard J. Tourillon, Chairman, President and CEO Tel (514) 907-1011

Patrick Levasseur, Vice-President and COO Tel: (514) 262-9239

http://www.hpqsilicon.com Email: [email protected]

____________________

1 The incorporation of lithium into an electrode in a lithium-ion battery

2 Source Marketandmakerts.com

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/9f7a4003-c0f6-4b77-b885-6e2b6138f49c

Silicon Vs Graphite

Gravimetric and Volumetric Capacity Silicon Versus Graphite

Tags: CSE, High Purity Quartz, High purity silicon, stocks