Gratomic Inc. (“GRAT” or the “Company”) (TSXV:GRAT)(OTCQB:CBULF)(FRANKFURT:CB81)(WKN:A143MR) announces the arrival of both the custom-built Material Hopper and Graphite Chipper to the Aukam mine site from South Africa. Excavation and preparations on the foundations for the Filter Press, Chipper, Cyclone, and Material Hopper have been successfully completed.

Two separate foundations were constructed to accommodate the commercial Filter Press. The equipment will be strategically placed one meter from the base of the product thickener tank. This will establish the shortest distance between the equipment for the graphite concentrate slurry to effectively enter the filter press from the product thickener tank. The press will be fitted onto two separate steel legs, with a custom-built catwalk surrounding the entire unit. This ensures staff safety when working around and servicing the equipment. Upon securing the Filter Press on the new foundations, a conveyor will be positioned below the output of the Press and placed at a 12° angle to more efficiently feed the graphite cake concentrate into the material chipper.

At 16 feet long, the Filter Press will have the capacity to process 5 tonnes of graphite concentrate per hour and will reduce the moisture content up to 92% before the concentrate enters the custom-built chipper. It will then make its way from the chipper into the rotary drying unit. Water that has been extracted from the filter press will be routed back to the settling reservoir tanks. From there it will be recirculated through the custom designed water filtration and deionization unit for continued use in the commercial processing plant. The Filter Press is a large component of the Company achieving its goal of a 95% water recycling rate during the graphite processing phase.

The company’s custom-built material chipper will be placed on a separate concrete foundation from the filter press. A two-tonne capacity hopper has been constructed adjacent to the chipper’s output to supply a continuous feed of graphite cake material to the rotary dryer unit. These components will complete the drying circuit of the Aukam 20,000 tonnes per annum commercial graphite processing plant.

The Material Hopper foundation work has been completed in conjunction with the cyclone foundation work. Once the concrete has cured, the custom-built hopper will be installed and mounted onto its new foundation. A supply conveyor will be installed and positioned to feed the material hopper with graphite containing material from the previously installed crushing and screening circuit. The variable speed drive screw conveyor (VSD) that is mounted inside the hopper will be positioned to feed the already installed commercial-sized rod mill. The material hopper is designed to hold 80 tonnes of material to allow for a 1 and a half days’ supply buffer to the processing plant (see press release November 20th, 2020).

“As the final construction is being completed on the Company’s custom-built processing plant, we would like to once again thank all of our mine workers, employees, contractors, and manufacturers, both on and off site, for all of their continued hard work and support.” says President and CEO, Arno Brand.

“The careful studies and analysis that based the engineering design of these exclusive, custom built pieces of equipment, will continue to ensure that Gratomic takes all necessary steps to deliver operational excellence at a benchmark level in the graphite industry”, says Amrando Farhate, COO & Head of Graphite Marketing and Sales.

About Gratomic Inc.

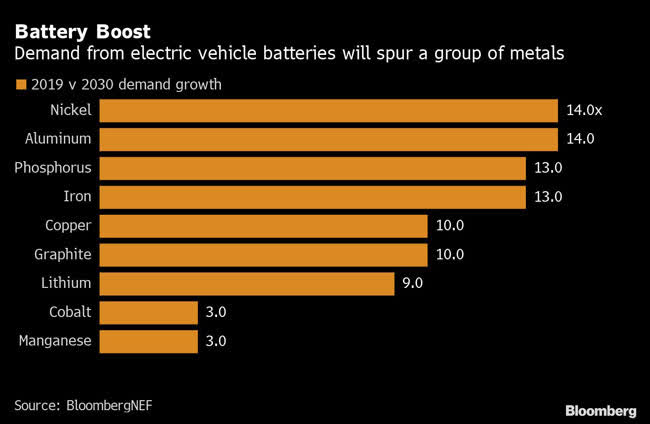

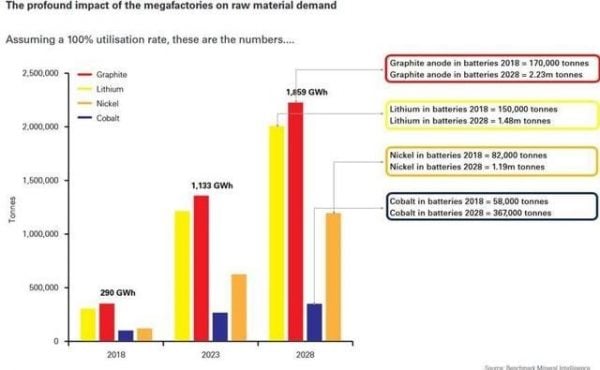

Established in 2014, Gratomic is an advanced materials company focused on low-cost mine to market commercialization of carbon-neutral, Eco-friendly, high purity vein graphite and is set to become a key player in EV and Renewable Resource supply chains. Gratomic Inc. is a leader among peers, anticipating full operational capabilities in late 2020 and aiming to transition to an open pit operation as early as the end of 2021.

Gratomic is in the process of solidifying its development plans for micronization and spheronization of its clean Aukam graphite. This significant milestone is a small, additional step in the Company’s existing Eco-friendly processing cycle and will allow its naturally high purity graphite to meet ideal North American battery grade standards for use in Li-ion battery anodes.

The Company promises to deliver mine-to-market traceability and guaranteed quality control. This will be accomplished by providing documented tracking on all graphite generated at its flagship Aukam Graphite Project. The tracking will begin at Aukam and will be verified at every stage during transport.

Two off-take purchase agreements are currently held for lump-vein graphite sourced from Gratomic’s Aukam Graphite Project in Namibia, Africa. Fulfillment of the contracts is slated to begin in 2021. The agreements exist with TODAQ and Phu Sumika.

TODAQ is an innovative tech company and will partner with Gratomic on its mine-to-market commodity tracking.

Phu Sumika is a large global graphite supplier to battery and lubrication companies.

Gratomic Inc. is listed on the TSX Venture Exchange under the symbol GRAT.

For more information: visit the website at www.gratomic.ca or contact:

Arno Brand at [email protected] or 416 561-4095

Subscribe to the link below to receive news and updates

https://gratomic.ca/contact/

“Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.”

Forward Looking Statements:

This news release contains forward-looking statements, which relate to future events or future performance and reflect management’s current expectations and assumptions. Such forward-looking statements reflect management’s current beliefs and are based on assumptions made by and information currently available to the Company. Investors are cautioned that these forward-looking statements are neither promises nor guarantees and are subject to risks and uncertainties that may cause future results to differ materially from those expected. These forward-looking statements are made as of the date hereof and, except as required under applicable securities legislation, the Company does not assume any obligation to update or revise them to reflect new events or circumstances. All of the forward-looking statements made in this press release are qualified by these cautionary statements and by those made in our filings with SEDAR in Canada (available at www.sedar.com).

SOURCE: Gratomic Inc.