TORONTO, ON /October 6, 2020 / Gratomic Inc. (“GRAT” or the “Company”) (TSXV:GRAT) (OTC Pink: CBULF) (FRANKFURT:CB81) (WKN:A143MR) announces a Aukam Graphite Property construction update.

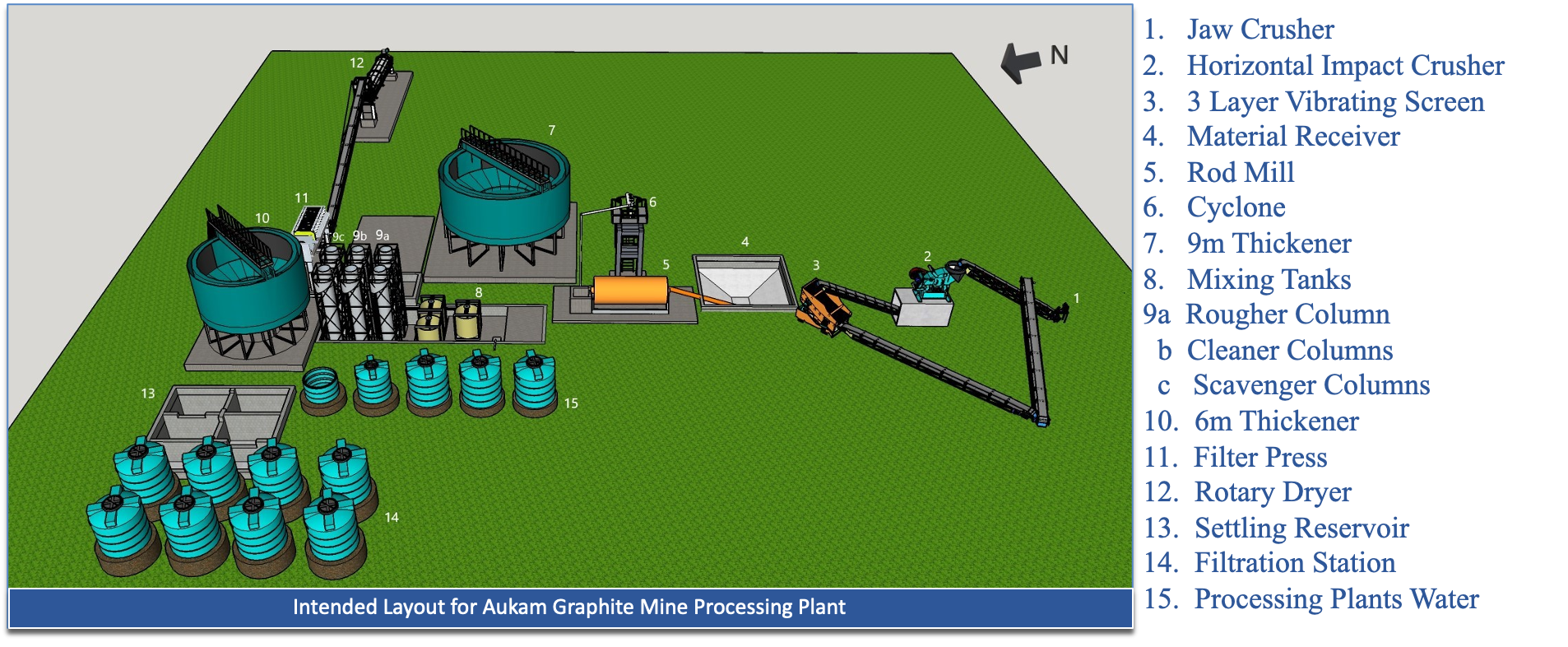

The Gratomic team has completed the excavations intended to contain the concrete foundations that will accommodate the custom designed processing equipment including material thickener, cyclone, material hopper, settling reservoir, and filter press. Gratomic is currently preparing to begin pouring concrete in these areas the second week of October.

The current pilot sump area will be designated to house the new floatation columns and mixing tanks. The filter press area has been prepared and excavation is currently scheduled to begin October 6th on the product dryer area.

Final general assembly and layout of the Aukam processing plant have been completed. On site Management has received the cement from Pupkewitz Megabuild – Keetmanshoop. Aggregate and bricks were received from Dolerite Brick & Sand CC, which will be utilized in the construction of the settling reservoir and key foundations.

Manhattan Process Engineering, a South African based engineering firm, has provided the Company with detailed Civil Engineering reports to complete the concrete construction on site. This included detailed bending and manufacturing parameters to meet foundational specifications for the necessary rebar, which has recently been delivered to site.

Pro Edge steel, a local engineering and fabricating company, has also been engaged to build the steel frames, cat walks and rail guards required to complete the equipment installation and to maintain regulatory safety standards.

Gratomic has been successful in keeping the project on schedule in spite of National and Global COVID-19 restrictions, which has created various workplace constraints. The Team has implemented the new standards efficiently and effectively, adapting quickly to the new workplace safety standards.

“Our Namibian team is working diligently to complete construction in a safe and timely manner, their efforts are greatly appreciated,” said President and CEO, Arno Brand.

“Gratomic will complete construction on its graphite plant in Namibia in the coming weeks, proving that 2020 can still deliver good news when you have a committed and knowledgeable team”, said COO & Head of Graphite Marketing and Sales, Armando Farhate.

About Gratomic Inc.

Gratomic is an advanced materials company focused on mine to market commercialization of graphite products and components for a range of mass market products. The Company currently holds two off-take purchase agreements for graphite product sourced from the Aukam facility. One agreement is with TODAQ and the other is with Phu Sumika. The Company is listed on the TSX Venture Exchange under the symbol GRAT.

For more information: visit the website at www.gratomic.ca or contact:

Arno Brand at [email protected] or 416 561-4095